Materials science probably does not come to mind when most people think of Amazon, but materials play a foundational role in almost everything we do. Materials often dictate what is possible in the physical world, from the thermal properties of materials used in our Echo devices to the fracture strength of lightweight structural materials used in our future low-Earth-orbit satellites.

Materials also play an outsized role in the area of sustainability. For example, global materials production contributes over 20% of all greenhouse gas (GHG) emissions, and over 75% of these emissions are generated from just four materials sectors: cement, steel, pulp and paper, and plastics.

Of all the materials used today, plastics are the fastest-growing category and offer the greatest opportunity for innovation. In joining the BOTTLE™ Consortium, led by the National Renewable Energy Laboratory (NREL), Amazon aims to help develop the foundational technologies that will enable the full life cycle of plastics to be net-zero carbon. From a scientific perspective, this requires rethinking plastics at the molecular level and developing new technologies that will keep these molecules in use.

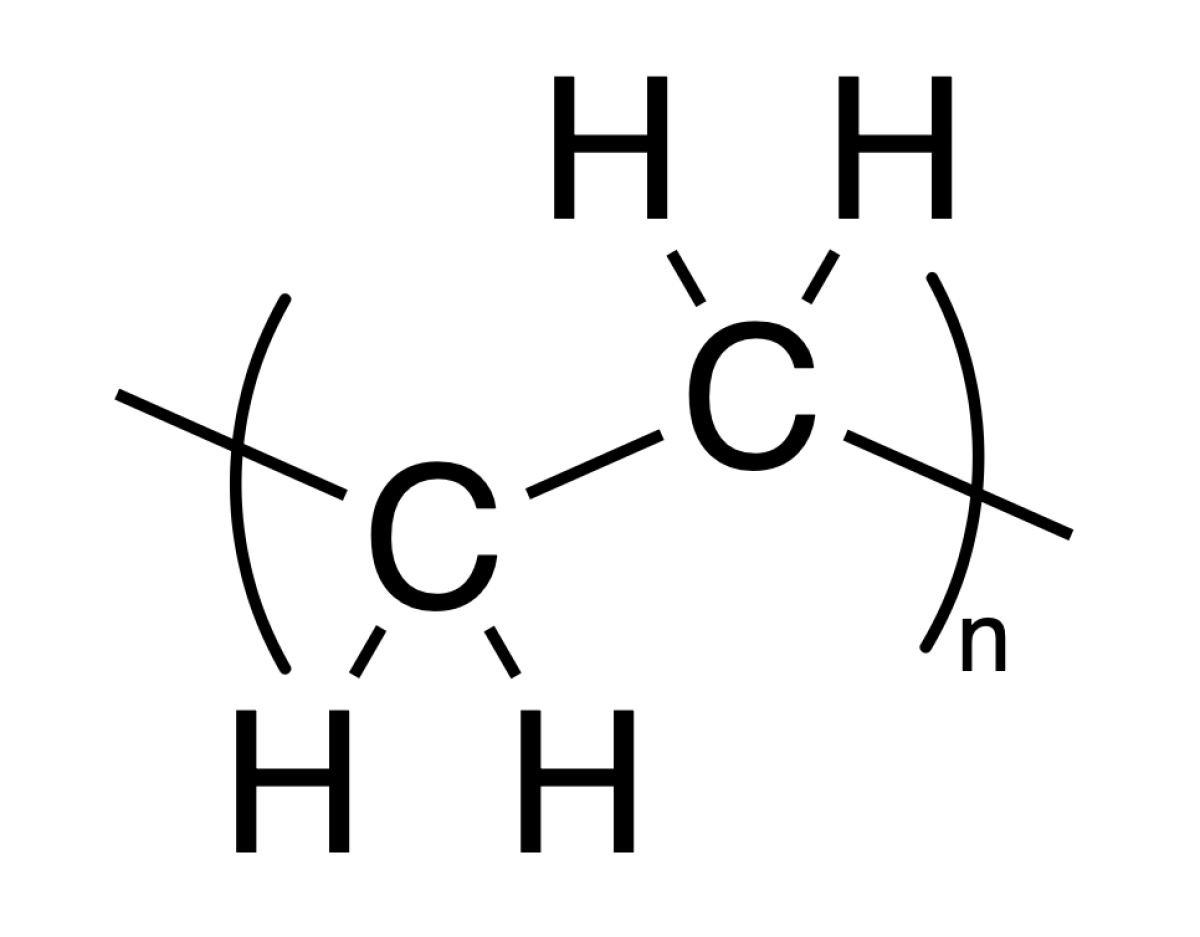

Today, the most commonly used plastics are polyolefins, which include polyethylene and polypropylene, and the most common application for these materials is packaging. Recently, Raoul Meys and collaborators published an article in Science describing the feasibility of achieving net-zero, or even net-negative, carbon emissions for the full life cycle of these and other existing conventional plastics.

In this situation, the terms “net-zero” and “net-negative” mean that the sum of the total emissions associated with the life cycle of the material is zero or negative, respectively. This is possible when the carbon sequestered throughout the life cycle of the material, either from biomass feedstock or carbon capture technologies, equals or exceeds the total carbon emissions associated with materials production and end-of-life.

Based on the model Meys and collaborators developed, net-zero, or even slightly net-negative, carbon emissions are possible over the life cycle of plastics if we create a “circular carbon pathway” that combines mechanical recycling, chemical recycling with carbon capture, and feedstock derived from biomass and/or captured carbon. In essence, the carbon in the molecular backbone of these plastics should come from CO2 that is pulled out of the atmosphere (either through technological or biological means), and we should expand known recycling technologies that will keep the carbon in use as long as possible.

More on materials

Read more about Amazon's collaboration with the National Renewable Energy Laboratory and the BOTTLE Consortium on About Amazon.

Although the research by Meys and team shows a challenging yet feasible path toward net-zero carbon emissions for plastics, there are drawbacks to relying solely on existing commodity materials and known recycling technologies. The strong carbon-carbon bonds in polyolefins are difficult to break down, so in cases where mechanical recycling is not cost-effective — or even possible, due to contamination — energy-intensive chemical recycling processes (pyrolysis or gasification) would be required to recover and reuse the carbon. Likewise, conventional polyolefins with a carbon-carbon molecular backbone don’t break down easily in natural environments, an important consideration in cases where these materials may not make it into a recycling stream.

Amazon’s recent partnership with the BOTTLE (Bio-Optimized Technologies to keep Thermoplastics out of Landfills and the Environment) Consortium aims to help overcome some of these drawbacks and accelerate the path toward more-sustainable plastics.

Deconstructable waste

The goal of our work is to develop new technologies that will not only enable but also encourage keeping the carbon in plastics in use by ensuring it is both technically and economically viable to recover and recycle these materials at the end of their life. One objective of our work with the BOTTLE Consortium is to develop an energy-efficient chemical processing technology that can break down or deconstruct a mixed waste stream of plastics with labile bonds (i.e., bonds that are easy to deconstruct) into valuable feedstock that can be used to make the same types of plastics (closed-loop recycling) or new plastics altogether (open-loop recycling). And in the cases where these materials don’t make it into a future recycling stream, the molecular structure of these materials can be designed to biodegrade in natural environments.

By developing a new deconstruction technology that can handle a mixed waste stream of plastics, we will be eliminating the need for excessive sortation of the materials before deconstruction. This will also help accelerate scaling of the technology because of greater available-material volumes, and the technology itself will not be dependent on the commercial success of a single type of material.

An additional objective of the initial work we are doing with the BOTTLE Consortium is to develop new plastics that could be made from the chemicals coming out of this new deconstruction process. In some cases, closed-loop recycling may make the most sense. In other cases, developing new polymers from the deconstructed materials may be a better option.

Our plan is to synthesize new materials from the deconstructed plastics and process them into films to understand their structure-property relationships and then develop a path towards recyclable-by-design replacements for packaging applications, while also ensuring these materials could be composted in an industrial facility or safely degrade in natural environments.

We envision this new flexible deconstruction process as a flywheel, where the materials that require the least amount of time and energy to break down and recover will lead to lower-cost feedstock for new-materials production, leading to lower-cost materials. The lower costs of these materials will then further incentivize their use over traditional plastics. In addition, we anticipate that the materials that more easily break down in this new process will also have the added benefit of being more likely to be compostable or to easily degrade in natural environments.

Compostable recycling

This may lead to the question why. Why develop a new technology that can recycle plastics that can naturally degrade? Why not just help develop end-of-life pathways to compost those materials? There are two main reasons why we believe this is an important path to pursue.

The first is that we want to invent technologies that will ultimately incentivize the broad use of materials that can naturally degrade in the environment but are recycled because of their economic value as feedstock for new materials. This will reduce the need for additional feedstock for making new materials, which will reduce carbon emissions, while also ensuring plastics do not persist in the environment in the cases where they do not make it into a managed waste stream. This is not possible with conventional plastics but could be possible with new emerging plastics as the production and use of these materials grow, and new recycling technologies are developed.

The second reason is that these new emerging plastics have the potential to enable a more efficient recycling system. Plastics that are biodegradable, either in a compost pile or in the natural environment, are fundamentally easier to deconstruct into intermediate chemicals than conventional plastics are. This opens the possibility for efficient processes that can infinitely recycle the carbon molecules in these materials without degradation of properties (e.g., mechanical recycling) or the substantial amounts of energy needed to deconstruct strong carbon-carbon bonds (e.g., pyrolysis).

Ultimately, the success of this work at scale will require a fundamental shift in both the plastics that are used in our everyday lives, especially plastics used in applications such as food packaging, and the recycling systems and infrastructure to keep these materials in use. Effecting that shift is a daunting task. But knowing that Amazon started out as an online bookstore serving customers out of a garage provides hope that even daunting tasks are achievable.