Each day, Amazon receives millions of orders. For each one, it makes a promise about when those items will show up on customers’ doorsteps.

Amazon’s fleet of more than half a million mobile robots is critical to meeting those deadlines. The typical Amazon fulfillment center has four floors, each several football fields in size, and 4,000 or more robots shuttling products to stations where associates select them for shipment. In some buildings, additional robots then sort those outgoing packages by zip code for delivery.

For Amazon Robotics researchers, the sheer number of robots requires some creative problem solving.

“Imagine that we want our robots to pick up and deliver as many items as possible during a set amount of time,” said Michael Wolf, a principal applied scientist at Amazon Robotics AI. “At first, we can increase throughput by adding more robots. But at a certain point, their sheer numbers start to cause congestion. The robots can interfere with each other and decrease the efficiency of the overall system.”

This is a challenge few organizations face. Amazon, because of its enormous scale and the need to delight its customers, has become a leader in utilizing robots while its science teams work to keep congestion from impacting operational efficiency.

Joey Durham, a senior manager of research and science for Amazon Robotics, has helped lead the way. He joined Kiva Systems, a pioneer in warehouse robots, just before Amazon acquired the company 10 years ago. At the time, the average Kiva customer used about 250 robots. Amazon’s vision was to push far beyond those boundaries.

“When we first started looking at it, we thought it would take more than 8,000 robots to keep an Amazon fulfillment center running,” Durham said. “There just was not enough room for them all. That’s when we said, ‘Wow, we really have to solve the congestion problem.’ And we have addressed it — we’ve gotten dramatically more efficient.”

While Amazon’s answers to the congestion challenge have evolved over time, its first solutions did not involve traffic management. Instead, it was all about helping robots make better decisions.

Understanding the floor

To understand why better decisions matter, consider how Amazon’s large rectangular fulfillment centers are laid out. Robots and four-sided storage shelves called pods, that contain millions of individual products, sit in the middle.

Pods containing products flow from the middle to stations spaced around the perimeter, where associates select the items needed to fulfill each order and place them in bins. When a particular pod is needed, a robot slips under the 1,000-lb pod, lifts it off the floor, and carries it to the station. This is the opposite of traditional warehouses, where workers travel miles of aisles daily, picking products one by one. By eliminating those trips, Amazon dramatically boosts productivity.

When Amazon receives an order, that order is assigned to the facility or facilities best able to fulfill it. A cloud-based computer system then decides which pod to use for each item in an order and which orders to process together to optimize the items delivered per pod. Like carpooling, picking more items per pod will reduce the amount of congestion that the robots will experience.

There are tradeoffs along the way. Amazon wants to store the maximum amount of goods on the floor. At the same time, it wants to move products to stations as efficiently as possible. “The challenge we’re always facing is how to increase storage space while still giving the robots enough room to maneuver,” Durham said.

Finding the flow

While good work allocation and route decisions smooth traffic flow and reduce unnecessary trips, managing the actual movement of robots is also important. To simplify the task, Amazon’s cloud computing service creates the virtual equivalent of a map of a city grid, on which robots can travel ‘north-south’ or ‘east-west’. Once a robot picks up a pod, the computing service creates a route to its final destination.

To optimize overall system efficiency and ensure the robots do not interfere with one another, Amazon has developed algorithms to coordinate robotic motion. The major challenge is creating plans fast enough to stay ahead of all the moving robots. One method the team uses is to compute “social rules” to guide the overall flow of robots to avoid traffic snarls, but also consider whether a robot should be allowed to break those rules to take a short cut and get to its destination more efficiently.

There are literally trillions of possibilities, and we have to solve these problems in real time.

Yet the dynamic nature of the fulfillment center means new orders arrive constantly, associates sign in and out of stations, and robots halt when they sense unexpected problems. Couple that with the number of pods and robots on the floor and Amazon’s scale, and you begin to realize the scope of the challenge. “There are literally trillions of possibilities, and we have to solve these problems in real time,” Wolf said.

Instead, the system seeks to constantly adapt the plan to conditions on the floor. “That reaction is more important to us than a globally optimized schedule,” Durham explained. “Ideally, we’d want both. So, we have to find this delicate balance between making sure the system is reactive and as optimal as possible.”

Going down the chutes

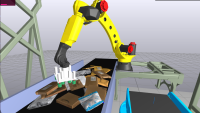

Once orders are packed and labeled, they go to the sortation center. There, associates and robotic arms pull packages off a conveyor, scan a bar code for destination information, and put each package on a small robot. The robot then weaves its way around an array of holes in the floor, each one representing a different group of zip codes. When it comes to the right one, it drops the package down the chute that goes to the loading dock below, where it goes out for delivery. A typical sortation floor has several hundred chutes and one thousand robots carrying packages to them.

Sortation, however, offers fewer options for optimization than fulfillment. In sortation, randomly jumbled packages roll down the conveyor and the system must deal with whatever it finds when the packages arrive.

So, Amazon Robotics researchers set about designing better traffic management patterns. Computers in the cloud plan a path for each robot. As on the fulfillment floor, the sortation center defines virtual streets that govern in which direction a robot can move — but here the streets are wider.

This gives rise to new problems and new algorithms to solve them. For example, what happens when several robots meet at a multi-lane intersection where some want to go straight or turn across oncoming traffic? To create a more optimal traffic flow, Amazon Robotics researchers are developing a new multi-agent planning system that will consider more robots at a time.

But even the state-of-the-art in multi-agent planning cannot plan fast enough for the thousand or more robots in an Amazon building. So, Durham’s teams are inventing “hybrid” solutions that combine fast planning for single robots with coordination techniques inspired by state-of-the-art methods. The goal, Durham said, is to find and resolve conflicts before they occur.

“Our goal is to create a plan that evolves,” Durham said. “We do not have the luxury to sit down at time-zero and come up with a perfect plan to get our robots moving. Instead, we start with the plan that is already up and running and that we resolved a second ago. Then, we update it with what has changed, what has gone wrong, and what new things have appeared and then reprioritize what robots should do.”

Building on increments

Multi-agent planning will be a major step forward, but Amazon has many more concepts in the works. Amazon has unparalleled experience with robots and its researchers want to use machine learning to better address common challenges. Then they can incorporate those learned policies and heuristics into an even better multi-agent system.

“As those robots are moving and looking around, they could assess what they see and look up the best policy in the cloud for dealing with it,” Wolf said. “It would save us the cost of duplicating those policies for every robot and it makes updating policies around the world easier.”

Amazon researchers are also developing “learning algorithms that allow the system to predict where patches of congestion will appear on the floor in the future, and also when they will disappear,” says Wolf, “This ability to anticipate makes planning even more knowledgeable.”

Amazon hopes to build on this work by reaching out to academics, who are exploring new concepts that are not yet ready for commercialization.

In October, the company announced a collaboration with Massachusetts Institute of Technology to create a Science Hub for robotics and artificial intelligence. There, Amazon is working with professor Cathy Wu, who uses machine learning to study the traffic flow of autonomous and human-driven cars in cities, and professor Cynthia Barnhart, who is an expert in operations research problems such as how to allocate robots to tasks.

They are exploring how to use machine learning to make robot fleets avoid congestion. Scientists at Amazon hope to leverage academic research to develop better algorithms for predicting congestion before it even appears and planning algorithms to avoid it.

The ultimate goal is to continue to extend technology in new directions. Machine learning-derived polices and better prediction and planning algorithms will enable Amazon to both ramp up the number of robots in its sortation and fulfillment centers and safely increase the flow of traffic. This will help customers to get their packages even faster.

That is only the beginning. Despite enormous strides, robotics remains a young and rapidly evolving science. Amazon, for example, funds multiple projects at several universities that range from machine learning and shared autonomy to hardware redesign and human-robot interaction. “We have an opportunity not just to use science improve products for our customers, but to support robotics researchers as a public good," said Jeremy Wyatt, senior applied science manager.

Yet Amazon also offers something more, something that comes only with scale.

“Amazon has the most challenging, full-scale, real-world problems I see in industry,” Wolf said. “If you want to have an impact on the real world, it is the place to be in robotics research. It gives researchers an opportunity to see our solutions deployed on hundreds of thousands of robots. And, because our operations are always evolving, there’s always an exciting new challenge to solve on the horizon.”